WELCOME TO ARC GROUP WORLDWIDE

ARC Group Worldwide, Inc. is a leading global advanced manufacturing service provider. Founded in 1987, the Company offers its customers a compelling portfolio of advanced manufacturing technologies and cutting-edge capabilities to improve the efficiency of traditional manufacturing processes and accelerate their time to market. In addition to being a world leader in metal injection molding, ARC has significant expertise in prototyping, advanced tooling, automation, machining, plastic injection molding, lean manufacturing, and robotics. ARC’s mission is to bring innovation and technology to manufacturing.

Metal Injection Molding

Metal Injection Molding (MIM), is a manufacturing process that utilizes an injection molding technique similar to the plastic injection technology, but instead of using plastic materials (polypropylene, polyamide, polyethylene, polycarbonate, etc.) uses a metal/thermoplastic feedstock to create components with complex geometries for a fraction of the cost of other manufacturing technologies (machining, stamping, casting, etc.)

Learn MorePlastic Injection Molding (PIM)

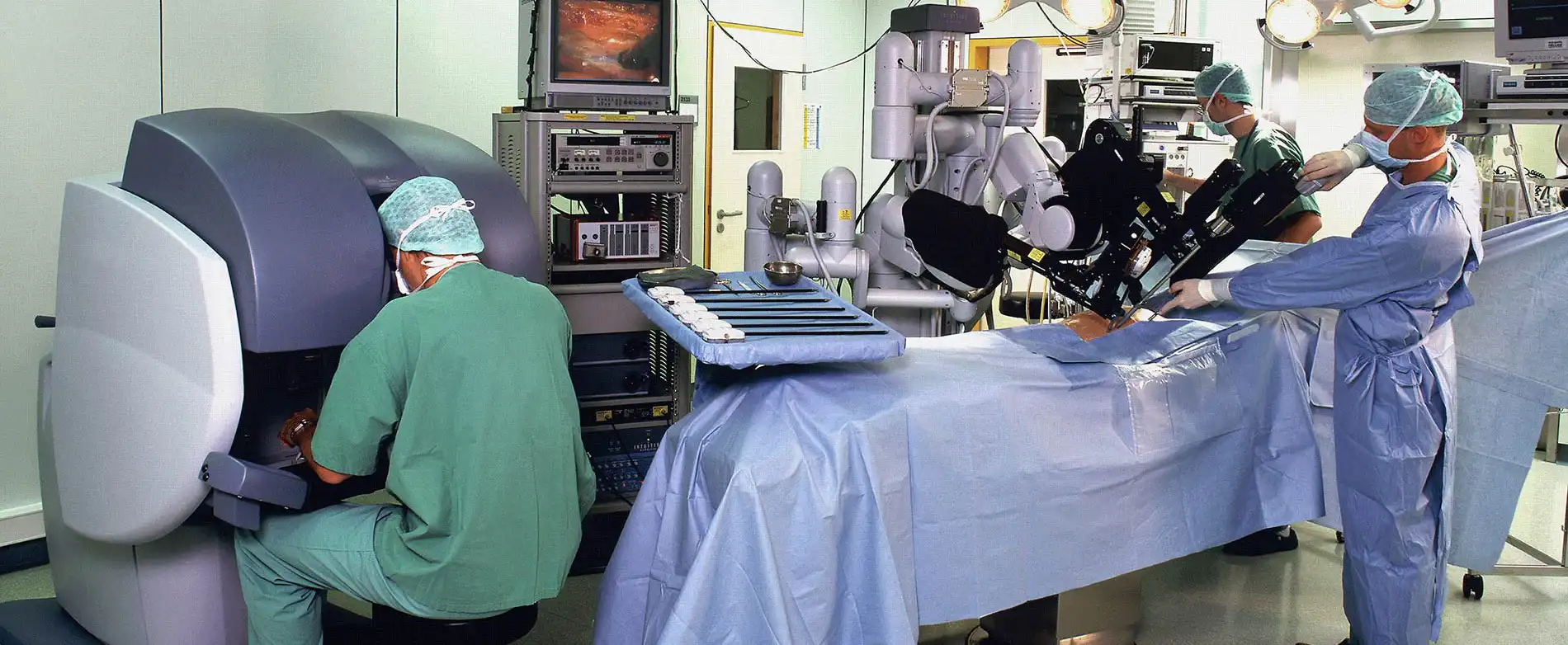

ARC Group Worldwide Inc. Plastic Injection Molding DIvision was founded on the principles of innovation and world class manufacturing. ARC combines a powerful blend of in-house tool building, highly engineered solutions, automation and full plastic injection molding capabilities. ARC services a variety of customers in major industries like Medical Device, Electronics, Consumer and Defense.

Learn MoreTooling

ARC tooling combines a powerful blend of in-house tool building, highly engineered tooling solutions and local vendors to service the tooling needs of our customers in industries like Medical Device, Electronics, Consumer and Defense.

Learn MoreCapabilities

1. Tool Making

2. ARC facilities have full in-house compounding

3. Injection molding

4. Debinding